Virtual replicas are transforming how aviation and defense systems are maintained, optimized, and deployed.

Introduction

In both civil aviation and modern defense, unexpected system failures can jeopardize safety, readiness, and cost-efficiency. Digital twin technology, which creates real-time virtual models of physical assets, is rapidly redefining how we manage, maintain, and optimize critical aerospace and defense systems.

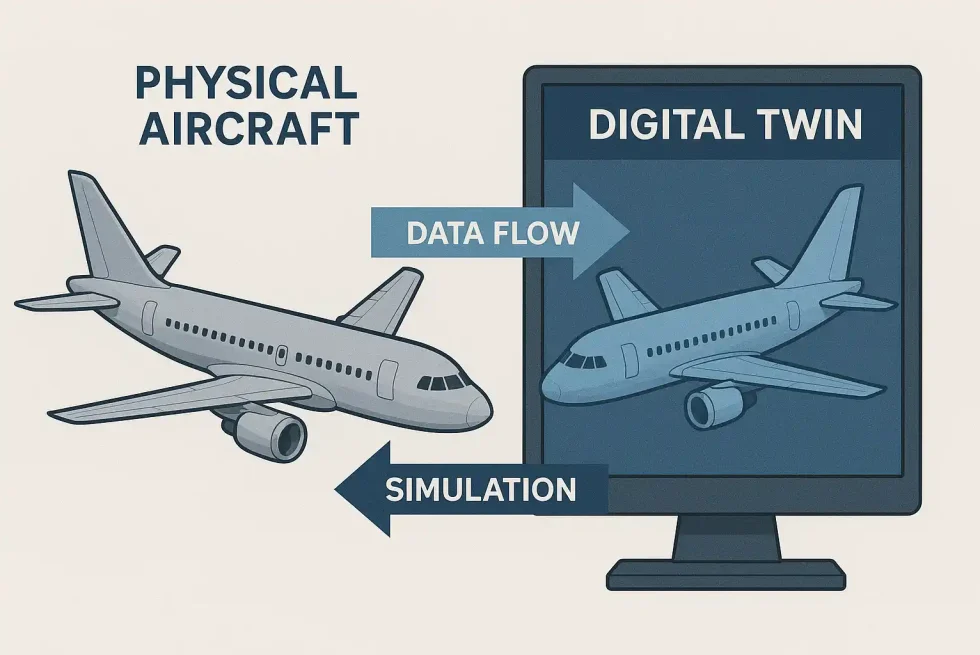

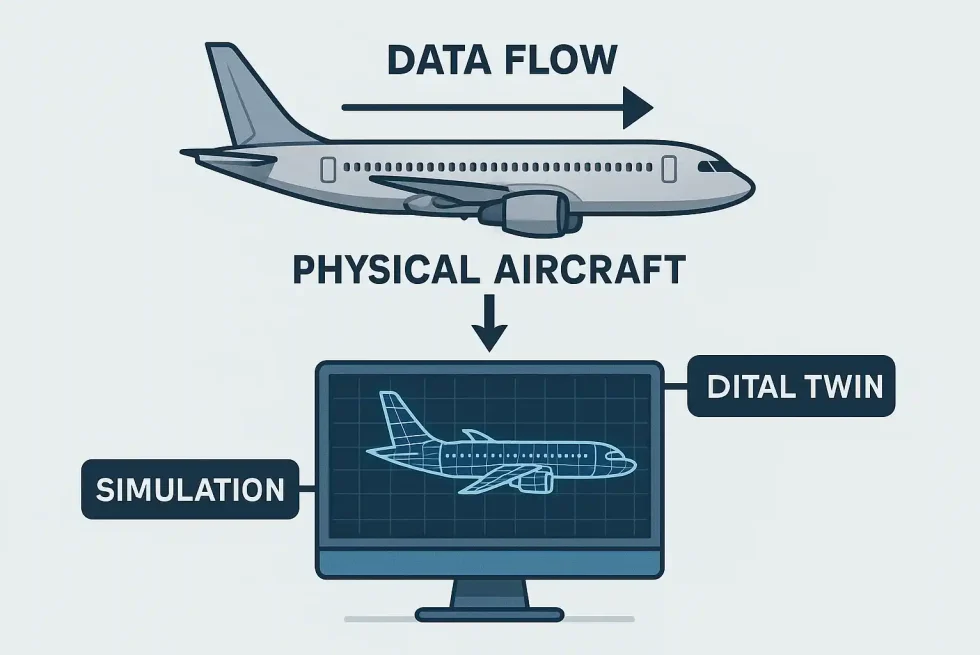

What Are Digital Twins?

Digital twins are continuously updated virtual replicas of physical assets—fueled by sensor data and simulation models. These models enable detailed analysis of system behavior under various operational scenarios. Aerospace applications include aircraft subsystems, propulsion units, and manufacturing processes. Such virtual representations facilitate performance prediction, wear simulation, and advanced decision-making

Applications in Aerospace & Defence

- Predictive Maintenance

Aerospace engineers use digital twins to forecast component failures and schedule maintenance proactively. This reduces unplanned downtime and avoids costly physical prototype testing .

- System Testing & Validation

Digital twins simulate extreme flight loads, thermal behavior, and failure modes. Rolls-Royce, for example, digitally tests jet engine actuators side-by-side with their real-world counterparts .

- Manufacturing Optimization

At Paris Air Show 2025, Siemens showcased how their Xcelerator platform and digital twins streamline production lines and shorten aircraft manufacturing lead times through real-time factory simulation - Operational Readiness in Defence

Defence organizations leverage digital twins for mission planning and fleet management, reducing decision-making cycles from months to days

Benefits to the Industry

| Benefit | Outcome |

| Safety | Early detection of system faults before they affect operations |

| Cost Reduction | Fewer physical tests, less downtime, longer part lifespans |

| Faster Development | Less prototyping, shorter R&D cycles |

These advantages are well documented in both academic studies and industry reports

Final Thoughts

Digital twins are transforming aerospace engineering—from safer aircraft to optimized manufacturing. Their adoption is rapidly increasing, shaping the future of aviation and defense. Aerospace firms who leverage these technologies are well-positioned to lead in innovation, resilience, and operational excellence.

✅Call to Action

Curious how digital twin technology can enhance your aerospace or defense systems? Connect with Aero Technicals to explore tailored solutions.

🔗 Sources:

Predictive maintenance systematic review – [sciencedirect.com]

Siemens Xcelerator showcase at Paris Air Show 2025 – [hiverlab.com]

Digital twin frameworks & reliability validation methods – [mdpi.com]

Rolls-Royce actuator digital twin example – [aerospacetestinginternational.com]